FAROSTUP

V10 e V12 Beehive

V10 and V12 Beehive

The design of our hives has a modular and compact construction. Antivarroa plinth; three body sizes consisting of removable walls and cover. The overlapping surfaces of the hive components (bottom, bodies, cover) have a profile that prevents the penetration of water from precipitation and reduces the risk of bees being crushed. The ventilation is done through some slits made in the seat profile of the cover. The flight board is also the door for closing the hive entrance.

The accessories we offer enable the beekeeper to solve a number of problems such as: feeding the bees with wet or dry honey; expelling bees from the honey storehouse; preventing the queen from laying eggs in the sheds; preventing unwanted swarming; reducing the size of the hive entrance; control of the result of antivarroa treatments; secure packing of the hive for transport in the pastoral area; manipulation of the hive with the help of removable handles.

We also offer a high-capacity pollen collector, which sits between the plinth and the nest (bottom pollen collector).

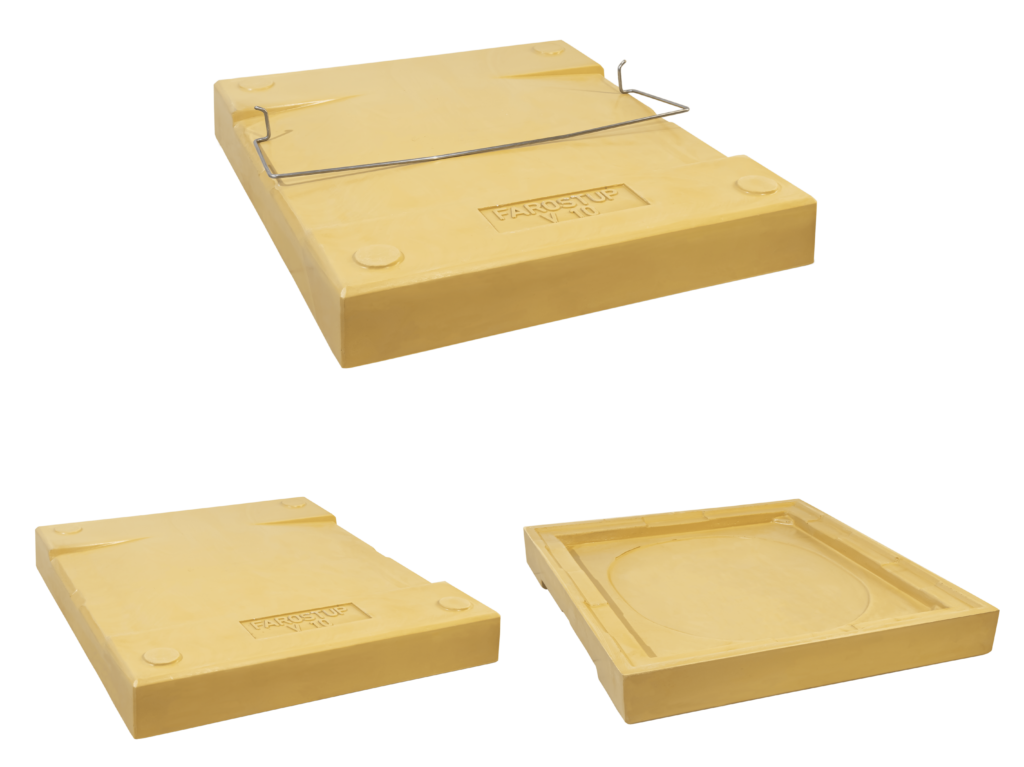

The lid

The lid (cover) has 40mm thick walls. For ventilation, 6 clearances are provided on the contour of the cover, which form the slots for ventilation. The position of the ventilation slots makes it impossible for precipitation to enter the hive. The clamp is an accessory of the cover, it is made of stainless steel and has the role of fixing the cover to the body of the beehive.

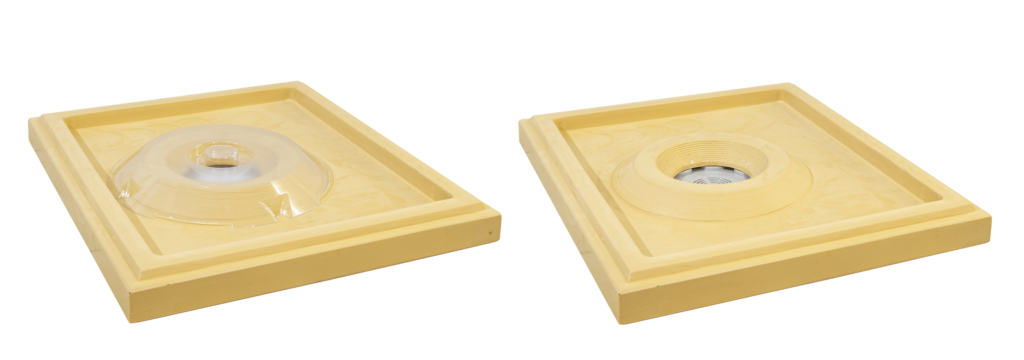

Feeder – expeller

Feeder – expeller is an accessory like a tray with a capacity of approx. 3l; with a frustoconical elevation towards the middle. The elevation is pierced by a round hole (φ 11 cm); for the circulation of bees. The Feeder – repellent accessory has a double function.

1. Feeding the bees. The feeding syrup is poured into the tray. A transparent plastic cap is placed over the truncated elevation. The cap is constructed in such a way that it allows the syrup to reach the base of the conical rise. The cap allows the bees to reach the syrup, but prevents them from entering the syrup and drowning. That is why it is called an anti-drowning device. In the case of feeding with cakes, the plastic cap is removed.

2. Expelling the bees from the honey shed. To fulfill this function, the accessory is placed between the nest and the honey store. Beforehand, a plastic rosette with 6-8 conical channels is mounted on the lower part. The bees will move through the conical channels to the nest where the queen is. After a few hours, most of the bees leave the honey store.

1/2 body – H=162 mm

The body is obtained by joining four walls made of PUR with a thickness of 40mm. The walls are joined with screws. In order for the joint to be done correctly on the joint surfaces of the walls, mother-father marks are visible. In the part where the thread of the screws for joining enters, the wall is reinforced with plastic dowels.

On request, we can deliver the front wall, with a slot for folding the flight board and an insurance plate (bolting).

Queen excluder

The queen excluder device is a PUR frame on which a hanneman grate is fixed. On the contour of the PUR frame, a closed secondary device is made with a plastic ruler, fixed with a screw. The anti-spill device is placed between the nest and the magazine. On the eve of the hatching of a new queen, the main hive closes and the secondary hive opens. In this situation, the bees can circulate in the hive, instead the matac is closed in the nest and prevented from causing swarming. This situation must be maintained for a limited time, after which the main drain must be reopened

1/1 body – H=300 mm

The body is obtained by joining four walls made of PUR with a thickness of 40mm. The walls are joined with screws. In order for the joint to be done correctly on the joint surfaces of the walls, mother-father marks are visible. In the part where the thread of the screws for joining enters, the wall is reinforced with plastic dowels.

On request, we can deliver the front wall, with a slot for folding the flight board and an insurance plate (bolting).

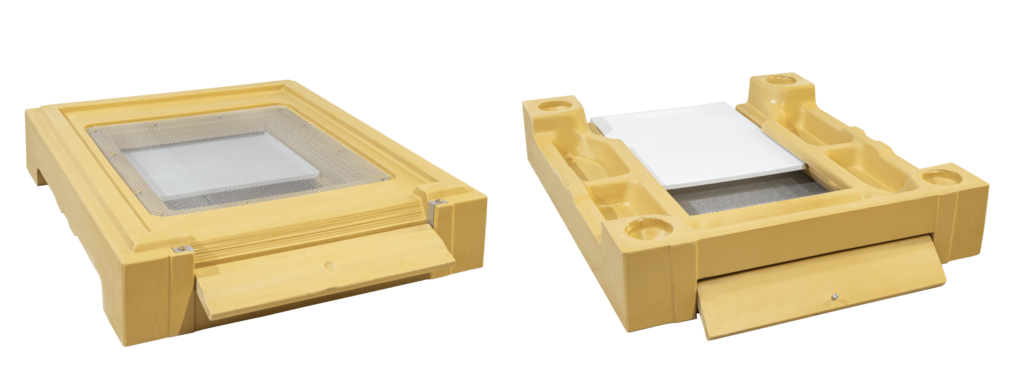

The bottom part

The bottom part is in anti-varroa construction. The bottom window is covered with stainless mesh. A plastic tray is inserted on some guides under the bottom net, which is used to close the bottom window and to monitor the anti-varroa treatments.

In the plinth, a 300 mm wide slat is used. The flight board is mounted with hinges at the base of the device. The closure is done by folding the flight flap.

For the V10 hive, we also offer the version with two hives: cold bed and warm bed.

So that those who want to be able to mechanically fix the nest on the plinth, on the bottom of the plinth I have provided 4 prints, which indicate the place where 4 wood screws must be screwed

φ4,5-5 x 95 mm.

Metal handles for handling and transport

Tie down strap handles for moving the hive are designed to grab the hive from two sides to move it. The handles are made in two lengths L= 50 cm. and L= 20 cm

Clamp for fixing the cover

The clamp is an accessory of the cover, it is made of stainless steel and has the role of fixing the cover to the body of the beehive.

The strap

The strap for wrapping the beehive is made of PP fabric with a metal or plastic buckle. The strap is delivered in a length of 3.5 ml. On request we can deliver other lengths. We recommend that the beehive be wrapped with webbing only during transport. Attached you can see a small video that shows how to fix the strap correctly.